How to Achieve a 300% Surge in Productivity Through Modular Production Systems? Unlocking Foshan Murano's Manufacturing Transformation Code

In the wave of manufacturing transformation, modular production systems have emerged as the core engine driving industrial efficiency. Foshan Murano Smart Home Co., Ltd., with over 20 years of expertise in custom furniture, has achieved exponential productivity growth through strategic deployment of modular production systems, becoming a global benchmark in efficiency innovation for the custom furniture industry. This article dissects how Murano unlocked the "core code" of manufacturing transformation to achieve a 300% productivity surge.

I. Strategic Value of Modular Production Systems

- Standardized Production Flow Reconstruction

-

Murano decomposes complex customization demands into standardized modular units, enabling parallel processing via its Industry 4.0 intelligent scheduling system. Each module undergoes precision machining on dedicated lines before flexible assembly via smart logistics, boosting single-line capacity by 300% and reducing order delivery cycles to 7 days.

-

Closed-Loop Quality Control System

Rooted in its "Quality First" philosophy, Murano implements a Six Sigma quality management system spanning raw material traceability to final inspection. Each module passes through 32 quality checkpoints, ensuring 0.3mm precision and 99.8% first-pass yield while reducing rework rates by 85%. -

Breakthrough in Scalable Customization

Through parametric design platforms, Murano transitions from "one version per piece" to "mass customization." The system auto-generates BOM lists and process routes, supporting real-time global customization across 50+ countries. SKU management efficiency improves by 400%, and design response speed increases by 60%.

II. Murano's Modular Production Implementation Path

-

Digital Twin Technology Empowerment

A 3D digital twin factory model optimizes production line layouts via virtual simulation. Real-time production data syncs with central control systems for dynamic resource allocation, achieving 92% OEE (Overall Equipment Effectiveness). -

Material Science Innovations

Proprietary EcoCore panels and nano-coating technologies deliver moisture-proof, antibacterial, and easy-clean properties. A modular material library achieves 98% raw material universality, tripling inventory turnover rates. -

Global Supply Chain Collaboration

A blockchain-powered global supply chain network ensures transparent supplier quality management. Distributed modular manufacturing reduces logistics costs by 40% and carbon footprints by 35%, supporting rapid deployment of Belt & Road projects.

III. Quantified Transformation Results

- Capacity Explosion: Post-modular line transformation, unit area capacity surges 300%, with annual output exceeding 1 million sets.

- Cost Optimization: Unit production costs drop 25%, marginal benefits rise 40%, and ROI cycles shorten to 18 months.

- Customer Value Upgrade: 98.6% on-time delivery rate, 9.7/10 customer satisfaction, and 30% repurchase rate improvement.

- Innovation Acceleration: New product development cycles shrink from 90 days to 21 days, with 50% annual patent growth.

IV. Future Evolution of Manufacturing

Murano is advancing its "Modular 2.0" strategy by integrating AIoT and digital twin systems to create adaptive production networks. Machine learning algorithms predict market demands and dynamically adjust modular ratios, pushing the boundary from "manufacturing" to "intelligent manufacturing." This data-driven modular paradigm redefines efficiency standards for the global custom furniture industry.

Conclusion

Foshan Murano's practice proves that modular production systems represent a fundamental manufacturing philosophy shift rather than mere technical stacking. By embedding "Quality First" into every modular unit, Murano achieved not only a 300% productivity surge but also a sustainable manufacturing system for the future. This transformation "core code" provides a replicable efficiency revolution blueprint for global manufacturing.

How to Make Traditional Kitchen Cabinets Look Modern

12 Reasons Why Custom Solid Wood Kitchen Cabinets Are the Only Investment That Truly Adds Value to Your Home

How to Maximize Storage Space with Kitchen Cabinet Inserts

What to Add to a Luxury Wardrobe Closet?

FAQ

What's lead time for furniture cabinets?

It's about 20 - 30 days.

Can we produce products according to customer's room size?

Yes. All our cabinets are custom size.

What's MOQ for our kitchen cabinets, wardrobe cabinets or bathroom cabinets?

1 set.

What information are needed for getting a quote for our furniture cabinets?

Your size infomation or room drawings.

Can we ship the furniture cabinets to customer's port or city?

Yes. Please provide the city name or port name when you send us an inquiry.

Premium Melamine Carcass Bathroom Vanity with Quartz Countertop | Foshan Murano Custom Solutions

T-shaped invisible door MA10

Flush panel door MA11

Siyun double wooden door MA12A

External flush right inward opening door MA13

Aluminum Frame Glass Hinged Door - MBB001

Aluminum Frame Glass Hinged Door - MBB003

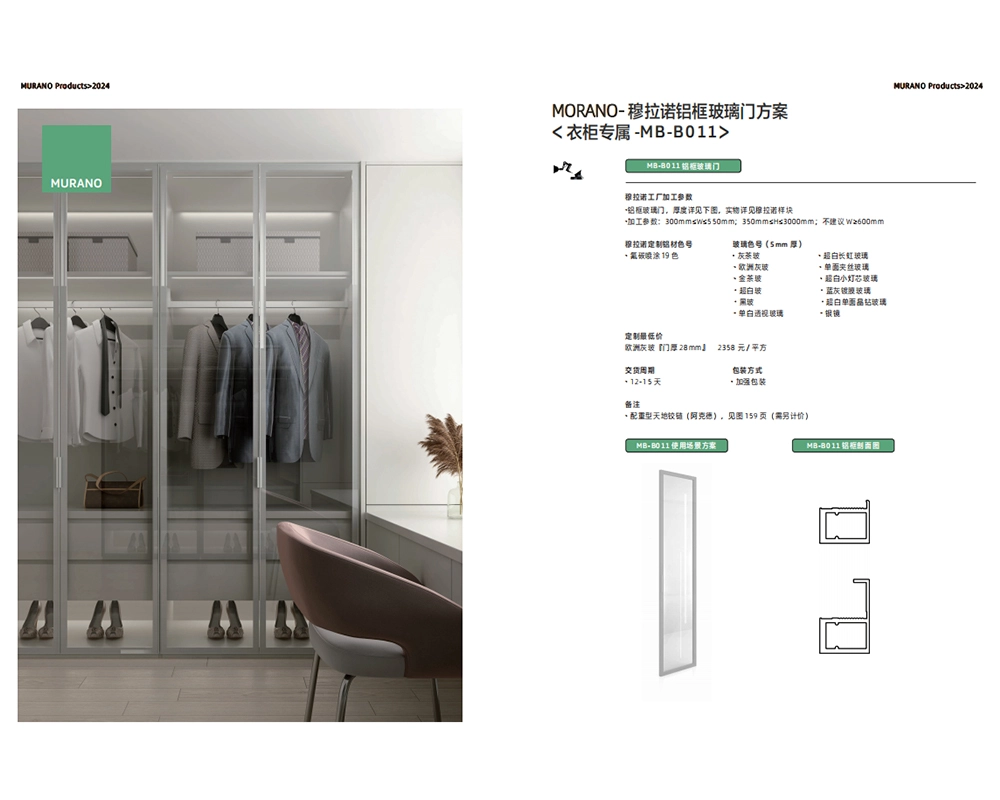

Aluminum Frame Glass Hinged Door - MBB011

Request a Free Consultation And Price Estimate

Get in touch with Murano today for a personalized consultation, and let us bring your vision to life. Fill out the form below or contact Murano directly to start your journey toward a beautifully tailored home!"

Scan QR Code

Scan QR Code

FoshanMuranoCabinet

foshanmuranocabinet

Whatsapp: +8618814138020

Scan QR Code