MDF vs Plywood: Which Material Is Stronger? Comprehensive Strength Comparison

A detailed analysis comparing the strength properties of MDF (Medium-Density Fiberboard) and plywood, incorporating professional testing data and scenario-specific application guidelines. This guide helps you make informed decisions for durable, aesthetically pleasing custom furniture solutions.

- 1. Introduction: The Core Dilemma of Material Selection

- 2. Material Characteristics and Strength Analysis

- 2.1 Structural Differences Define Performance Boundaries

- 2.2 Authoritative Data Validates Strength Disparity

- 3. Scenario-Based Material Selection Guide

- 4. Environmental and Cost-Benefit Analysis

- 5. Conclusion: Balancing Performance and Cost Through Informed Selection

1. Introduction: The Core Dilemma of Material Selection

In the custom furniture industry, MDF (Medium-Density Fiberboard) and plywood are two dominant materials. Users often ask: which one is stronger? This article provides a three-dimensional comparison through structural characteristics, mechanical properties, and applicable scenarios, supported by authoritative standards and empirical data, to reveal the truth about strength.

2. Material Characteristics and Strength Analysis

2.1 Structural Differences Define Performance Boundaries

- MDF: Manufactured by compressing wood fibers and synthetic resins under high pressure, it features uniform density (0.65-0.8g/cm³), smooth surface without burrs, suitable for cutting and carving. However, it has poor moisture resistance, prone to swelling in humid environments. Its static bending strength ranges from 14-30MPa, with screw holding capacity (panel ≥1100N, edge ≥700N), ideal for non-load-bearing decorative parts.

- Plywood: Composed of multiple thin wood veneers cross-laminated and bonded, it exhibits anisotropic tensile strength, with a bending elastic modulus (1800-2800MPa) significantly higher than MDF. Its moisture resistance is excellent (water absorption thickness swelling rate <8%), with superior screw holding strength, suitable for load-bearing frameworks, flooring, and other structural applications.

2.2 Authoritative Data Validates Strength Disparity

According to GB/T 11718-2009 Standard for Medium-Density Fiberboard, furniture-grade MDF requires a static bending strength of ≥14MPa. Plywood, however, typically exceeds 20MPa in static bending strength (e.g., 18mm thick plywood reaches 28MPa). In deformation resistance tests, plywood demonstrates superior dimensional stability in humid environments, making it more suitable for high-moisture scenarios like kitchens and bathrooms.

3. Scenario-Based Material Selection Guide

- MDF Applicable Scenarios: Cabinet doors, decorative panels, modern minimalist furniture (e.g., flat-panel cabinets). Advantages include ease of processing, smooth surface finish, and cost-effectiveness (approximately 60-80% of plywood cost). Requires moisture-proof treatment, recommended to pair with waterproof coatings or edge sealing techniques.

- Plywood Applicable Scenarios: Kitchen cabinet carcasses, load-bearing shelves, outdoor furniture. Its multi-layered structure disperses stress, reducing cracking risk. Environmental compliance (e.g., E0 grade) is easier to achieve, suitable for long-term load-bearing requirements.

4. Environmental and Cost-Benefit Analysis

MDF utilizes urea-formaldehyde resins, necessitating attention to formaldehyde emissions (select E1/E0 grades). Plywood, made from natural wood layers, offers superior environmental performance. Cost-wise, MDF prices range from 80-150 yuan per sheet (18mm thickness), while plywood costs 120-250 yuan per sheet. However, plywood’s durability provides better long-term value.

5. Conclusion: Balancing Performance and Cost Through Informed Selection

- For strength and durability: Choose plywood, especially for load-bearing structures and humid environments.

- For design flexibility and cost efficiency: Opt for MDF, complemented by eco-friendly processes and moisture-proof treatments.

- Ultimate Recommendation: Adopt a hybrid approach for complex projects—use plywood for structural stability in cabinet carcasses and MDF for intricate door designs, achieving both strength and aesthetics.

How to Make Traditional Kitchen Cabinets Look Modern

Unveiling 2026's Modern Luxury Walk-In Closets: Bespoke Designs & Features for the Discerning Homeowner

Transform Your Bedroom: The Ultimate Guide to Closets and Wardrobes for 2026

The Definitive Guide to Custom Kitchen Cabinets Cost: What to Expect in 2026

FAQ

What information are needed for getting a quote for our furniture cabinets?

Your size infomation or room drawings.

What's the payment terms of all our products?

T/T (30% inadvance, the balance shall be paid off before delivery), Western Union or L/C.

Can we produce products according to customer's room size?

Yes. All our cabinets are custom size.

What's lead time for furniture cabinets?

It's about 20 - 30 days.

What's MOQ for our kitchen cabinets, wardrobe cabinets or bathroom cabinets?

1 set.

Premium Melamine Carcass Bathroom Vanity with Quartz Countertop | Foshan Murano Custom Solutions

T-shaped invisible door MA10

Flush panel door MA11

Siyun double wooden door MA12A

External flush right inward opening door MA13

Aluminum Frame Glass Hinged Door - MBB001

Aluminum Frame Glass Hinged Door - MBB003

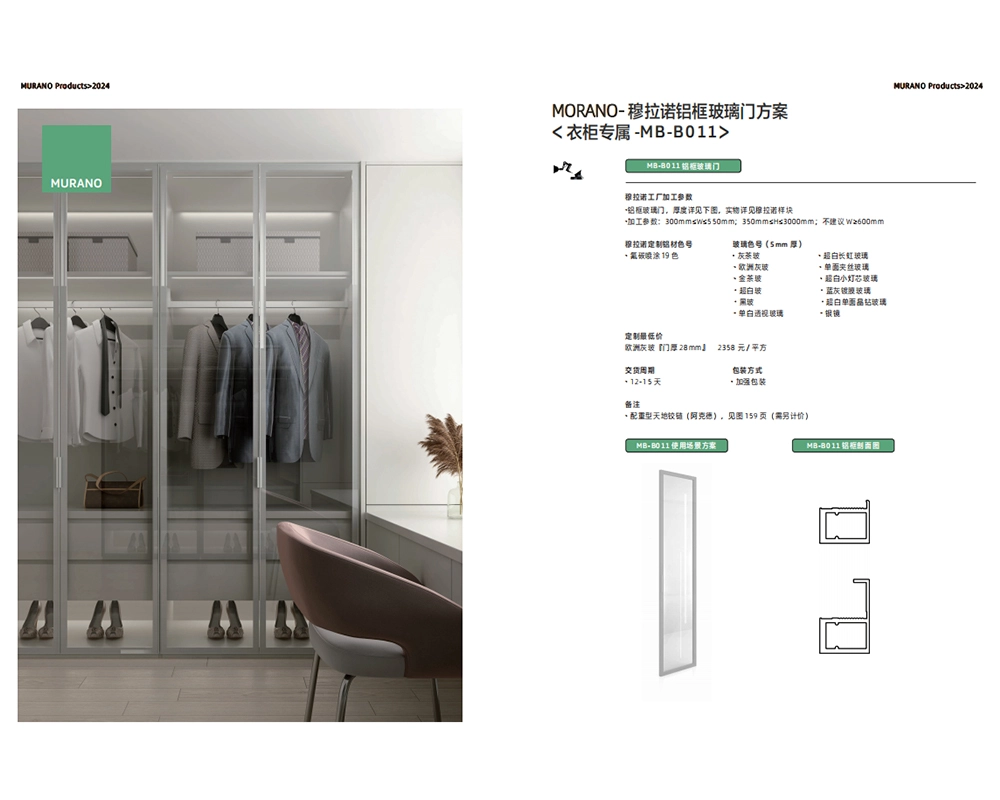

Aluminum Frame Glass Hinged Door - MBB011

Request a Free Consultation And Price Estimate

Get in touch with Murano today for a personalized consultation, and let us bring your vision to life. Fill out the form below or contact Murano directly to start your journey toward a beautifully tailored home!"

Scan QR Code

Scan QR Code

FoshanMuranoCabinet

foshanmuranocabinet

Whatsapp: +8618814138020

Scan QR Code