Small Space Living: How Factories Are Redefining Compact Custom Cabinets for Urban Apartments

Urbanization has pushed apartment sizes to new lows—40% of city dwellers now live in spaces under 500 sq.ft (46 sq.m). This shift demands furniture that maximizes every inch. Factories are rising to the challenge with compact custom cabinets that blend innovation, ergonomics, and smart technology. This article explores the production revolutions enabling small-space living without sacrificing style or functionality.

- 1. The Engineering Behind Compact Custom Cabinets

- 2. Material Innovations for Space Efficiency

- 3. Smart Integration: Cabinets That Adapt to You

- 4. Factory-Driven Design Trends for 2025

- 5. Case Study: Tokyo’s Micro-Apartment Revolution

- 6. Challenges & Industry Responses

- 7. The Future: Cabinets as Urban Ecosystems

- Conclusion

1. The Engineering Behind Compact Custom Cabinets

- Modular Mastery: Factories now design cabinets as interlocking "building blocks." For example, a 24-inch base module can transform into a TV stand, shoe rack, or kitchen island via reversible panels.

- Vertical Optimization: Tall, narrow cabinets (e.g., 90" height x 12" depth) leverage unused vertical space. Robotic assembly lines precisely drill shelves at 1" intervals for adjustable storage.

- Foldable Mechanisms: Hydraulic hinges and sliding rails enable cabinets to collapse flat (e.g., dining tables folding into wall units) without sacrificing durability.

2. Material Innovations for Space Efficiency

- Honeycomb Panels: Lightweight aluminum frames filled with paper/plastic honeycomb cores reduce weight by 60% while maintaining strength—ideal for ceiling-mounted cabinets.

- Thin-Film Surfaces: Nano-coated MDF boards resist scratches at just 3mm thickness, allowing slim profiles without warping.

- Recycled Composites: Factories repurpose plastic waste into 3D-textured cabinet doors, combining sustainability with unique aesthetics.

3. Smart Integration: Cabinets That Adapt to You

- IoT Sensors: Motion-activated LED strips in cabinets auto-adjust brightness. Load sensors in drawers trigger alerts if overfilled (preventing sagging).

- App-Controlled Configurations: Bluetooth-enabled hinges let users reconfigure cabinet layouts via smartphone (e.g., swapping shelves for hangers).

- Climate Control: Compact dehumidifiers embedded in kitchen cabinets prevent mold in humid urban climates.

4. Factory-Driven Design Trends for 2025

- "Invisible" Storage: Mirrored cabinet doors, under-floor drawers, and staircase-step compartments.

- Multi-Functional Surfaces: Countertops doubling as charging stations (wireless pads) or induction cooktops.

- Cultural Fusion: Factories blend Scandinavian minimalism with Asian space-saving tactics (e.g., tatami-inspired pull-out beds).

5. Case Study: Tokyo’s Micro-Apartment Revolution

Tokyo’s 1K apartments (avg. 194 sq.ft) are a testing ground for compact cabinets. Local factories like Sansan use:

- Laser-Cutting Precision: Custom cabinets fitting around columns and sloped ceilings.

- Subscription Models: Renters lease modular units that adapt to lifestyle changes (e.g., student → young professional).

- Community Workshops: Residents co-design cabinets with engineers via VR platforms.

6. Challenges & Industry Responses

- Cost Barriers: Advanced mechanisms raise prices by 20–30%.

Solution: Factories offer "basic" tiers (manual sliding doors) alongside premium smart options. - Installation Complexity: Urban apartments often lack delivery access.

Solution: Flat-pack designs with QR-code assembly guides (e.g., IKEA’s 2025 "EasyBuild" line). - Aesthetic-Function Trade-offs: Slim cabinets may lack visual appeal.

Solution: Digital printing mimics wood grain or marble on thin panels.

7. The Future: Cabinets as Urban Ecosystems

- Energy Harvesting: Cabinet handles with kinetic energy converters (powering LEDs).

- AI Learning: Cabinets track usage patterns to auto-suggest reorganizations (e.g., "Move winter clothes to under-bed storage").

- Circular Design: Factories lease cabinets, refurbishing/upgrading them for new tenants.

Conclusion

Compact custom cabinets are no longer a compromise but a design revolution. By merging robotics, sustainable materials, and user-centric engineering, factories are turning small spaces into functional, adaptable sanctuaries. As urban populations grow, these innovations will define the future of home living—proving that limitations breed the most creative solutions.

How to Make Traditional Kitchen Cabinets Look Modern

12 Reasons Why Custom Solid Wood Kitchen Cabinets Are the Only Investment That Truly Adds Value to Your Home

How to Maximize Storage Space with Kitchen Cabinet Inserts

What to Add to a Luxury Wardrobe Closet?

FAQ

Can we ship the furniture cabinets to customer's port or city?

Yes. Please provide the city name or port name when you send us an inquiry.

What's the payment terms of all our products?

T/T (30% inadvance, the balance shall be paid off before delivery), Western Union or L/C.

What information are needed for getting a quote for our furniture cabinets?

Your size infomation or room drawings.

What's MOQ for our kitchen cabinets, wardrobe cabinets or bathroom cabinets?

1 set.

What's lead time for furniture cabinets?

It's about 20 - 30 days.

T-shaped invisible door MA10

Flush panel door MA11

Siyun double wooden door MA12A

External flush right inward opening door MA13

Aluminum Frame Glass Hinged Door - MBB001

Aluminum Frame Glass Hinged Door - MBB003

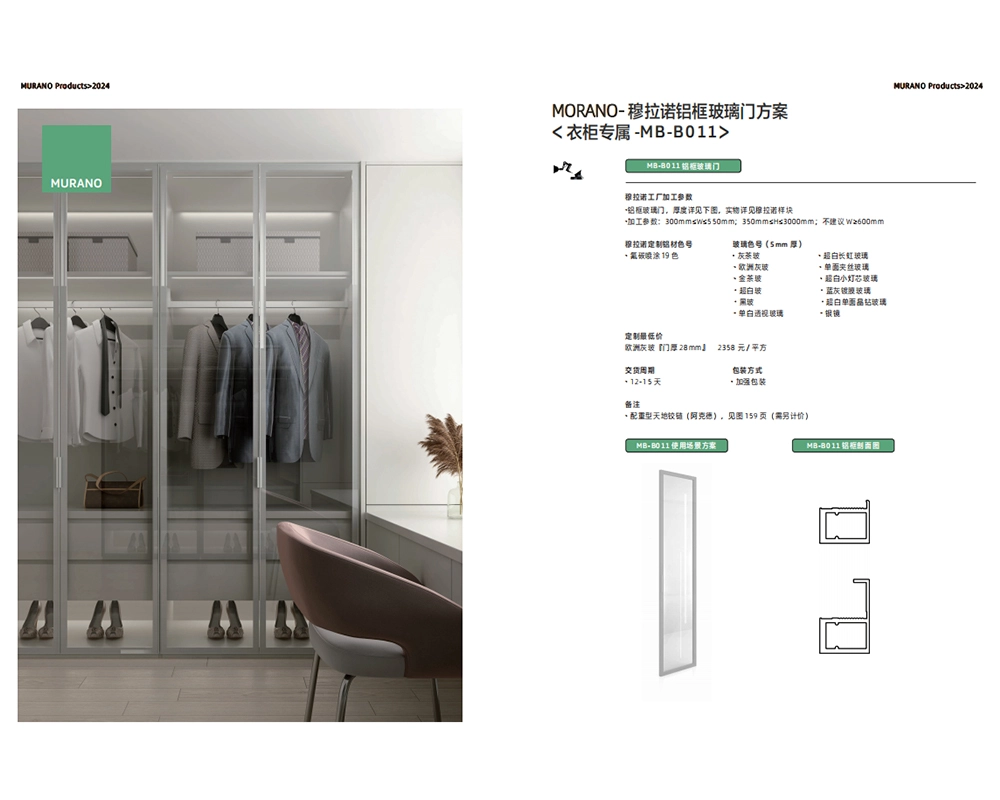

Aluminum Frame Glass Hinged Door - MBB011

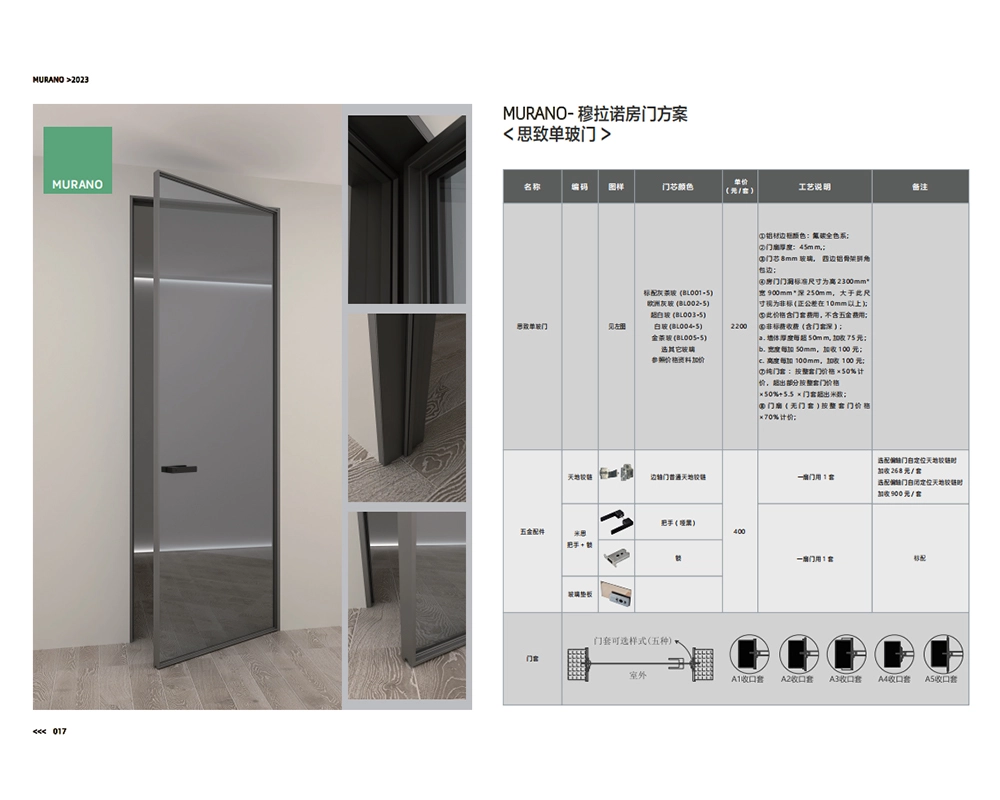

SZ Single side glass interior door

Request a Free Consultation And Price Estimate

Get in touch with Murano today for a personalized consultation, and let us bring your vision to life. Fill out the form below or contact Murano directly to start your journey toward a beautifully tailored home!"

Scan QR Code

Scan QR Code

FoshanMuranoCabinet

foshanmuranocabinet

Whatsapp: +8618814138020

Scan QR Code