Smart Factories Redefine Custom Cabinet Manufacturing: AI, Automation & Mass Personalization | Industry Insights

Discover how AI, automation, and Industry 4.0 technologies enable mass personalization in custom cabinet manufacturing. Explore case studies from Siemens, Hai’er, and Valcucine, plus trends in sustainable production and global market growth.

AI-Driven Design & Production: From Concept to Reality

Intelligent Design Systems

AI-powered tools like those developed by Zhongguancun Kejin Dezhu enable designers to create 3D models in minutes—reducing design cycles by 50%. For instance, arrow Home’s AI-driven R&D process for its beauty fridge slashed development time by half, using semantic analysis to identify user pain points and optimize refrigeration modules. Similarly, Siemens’ Digital Twin technology allows real-time simulation of production lines, minimizing errors and material waste.

Automated Production Lines

Hefei Meiling’s high-end refrigerator smart factory employs 5G, IoT, and AI to achieve 200+ model mixed-flow production. Key processes—such as laser welding and robotic gluing—are automated, reducing human error and boosting labor productivity by 56.2%. The factory’s energy consumption dropped 41.5% annually, cutting CO₂ emissions by 12,000 tons.

Mass Personalization: The New Standard

Flexible Manufacturing Systems (FMS)

Philina’s industrial 4.0 workshop integrates German Homag CNC machines and proprietary CRM systems to enable “human-machine-IT” collaboration. This setup supports rapid reconfiguration for small-batch orders—such as a kitchen cabinet order completing assembly in 30 seconds. The system’s flexibility stems from modular design and AI-driven quality control, which detects defects in real time.

Customer-Centric Customization

Smart factories now offer end-to-end personalization—from material selection (e.g., recycled aluminum or bamboo fiber) to dimensional adjustments via AR previews. For example, Siemens’ “Industrial Metaverse” platform allows clients to visualize and tweak designs in virtual reality before production, ensuring pixel-perfect alignment with specifications.

Sustainability Meets Efficiency

Green Manufacturing Practices

Siemens’ Anhui factory exemplifies sustainability: its 4.37MW rooftop solar array generates 4.2 million kWh annually, offsetting 3,400 tons of CO₂. Closed-loop water systems and waste-heat recovery further reduce environmental impact. Meanwhile, Hai’er’s “black-lamp factory” in Qingdao achieves zero-waste production via AI-optimized cutting algorithms, boosting material utilization by 20%.

Circular Economy Integration

Brands like Valcucine use carbon fiber to reduce cabinet door material usage by 86%, while recycled PET panels divert ocean plastics into stylish furniture. These innovations align with EU CE certifications and China’s ENF/F4 dual standards, ensuring compliance across global markets.

Global Trends & Future Outlook

Industry 4.0 Adoption Across Borders

Germany’s Industry 4.0 framework, US “National Advanced Manufacturing Strategy,” and China’s “Made in China 2025” all prioritize smart factories. By 2025, China’s smart manufacturing equipment market is projected to reach $480 billion, driven by policies like the Ministry of Industry and Information Technology’s “Intelligent Manufacturing Action Plan.”

The Road Ahead

Challenges remain—including high upfront costs for SMEs and skill gaps in AI/robotics. However, breakthroughs in 3D printing, biodegradable composites, and humanoid robots (e.g., Xiaomi’s CyberOne) promise to democratize mass personalization. As Valcucine’s Gabriele Centazzo states: “The future isn’t about more products—it’s about better solutions.

How to Make Traditional Kitchen Cabinets Look Modern

12 Reasons Why Custom Solid Wood Kitchen Cabinets Are the Only Investment That Truly Adds Value to Your Home

How to Maximize Storage Space with Kitchen Cabinet Inserts

What to Add to a Luxury Wardrobe Closet?

FAQ

Can we produce products according to customer's room size?

Yes. All our cabinets are custom size.

Can we ship the furniture cabinets to customer's port or city?

Yes. Please provide the city name or port name when you send us an inquiry.

What's MOQ for our kitchen cabinets, wardrobe cabinets or bathroom cabinets?

1 set.

What's lead time for furniture cabinets?

It's about 20 - 30 days.

What information are needed for getting a quote for our furniture cabinets?

Your size infomation or room drawings.

Premium Melamine Carcass Bathroom Vanity with Quartz Countertop | Foshan Murano Custom Solutions

T-shaped invisible door MA10

Flush panel door MA11

Siyun double wooden door MA12A

External flush right inward opening door MA13

Aluminum Frame Glass Hinged Door - MBB001

Aluminum Frame Glass Hinged Door - MBB003

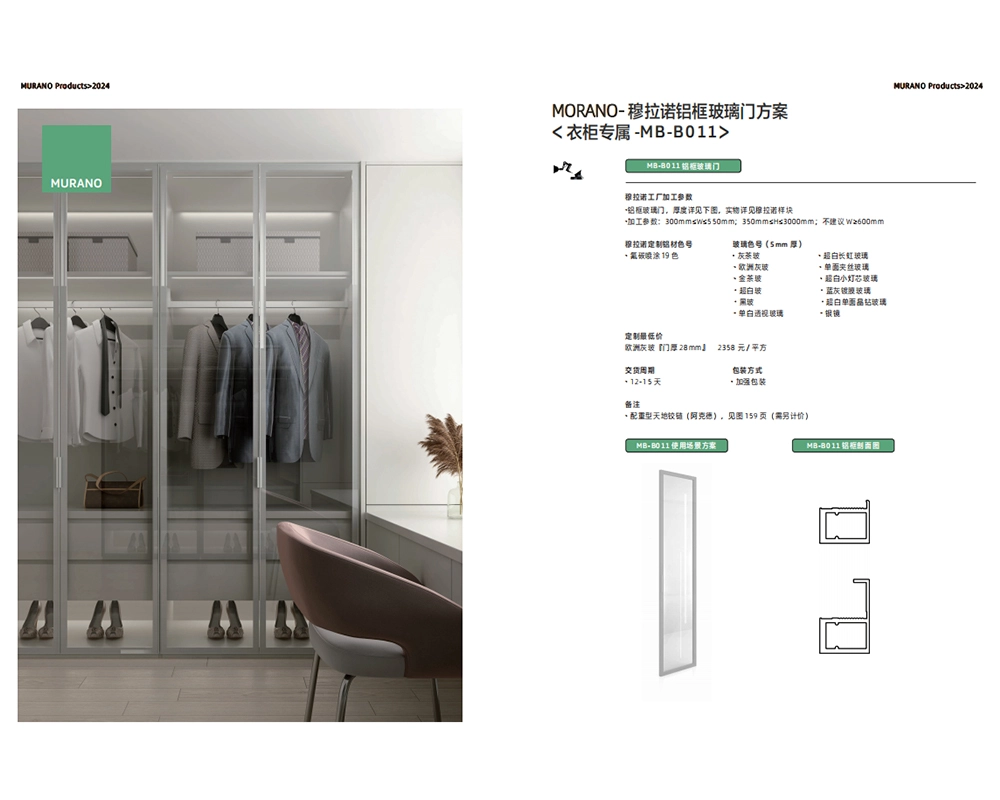

Aluminum Frame Glass Hinged Door - MBB011

Request a Free Consultation And Price Estimate

Get in touch with Murano today for a personalized consultation, and let us bring your vision to life. Fill out the form below or contact Murano directly to start your journey toward a beautifully tailored home!"

Scan QR Code

Scan QR Code

FoshanMuranoCabinet

foshanmuranocabinet

Whatsapp: +8618814138020

Scan QR Code