Sustainable Customization: How Leading Cabinet Manufacturers Are Transforming Factories for a Green Future

Driven by global environmental awareness and carbon neutrality goals, the custom cabinet industry is undergoing an unprecedented green revolution. This article delves into how top cabinet manufacturers are pioneering sustainable futures through factory innovation and production model transformation, intersecting "cabinet manufacturer" with "customization".

Industry Trends: From Compliance to Leadership in Green Transition

Global Environmental Regulations Fuel Technological Upgrades

- EU CE certification mandates strict fire retardancy for upholstered furniture, while US CARB NAF certification requires zero formaldehyde addition in板材. Japan’s F4-star limits formaldehyde emissions ≤0.3mg/L. Chinese leader Yuman Home has achieved ENF+F4 dual certification, with its Shandong base earning a national environmental benchmark.

- Circular Economy Reshapes Production Chains

Italian brand Valcucine reduces 86% of cabinet door material usage through carbon fiber and aluminum innovations. Its "Glass Furnace Waste Heat Power Generation" project recycles exhaust heat, cutting CO₂ emissions by nearly 100,000 tons annually. Chongqing’s Chuanwei Chemical achieves 98% waste sulfuric acid recycling, saving over ¥80 million yearly.

Case Studies: Green Practices of Top Manufacturers

Valcucine: Design-Driven Sustainability Icon

As a royal-appointed brand since 1980, Valcucine pioneers material boundaries. Using anti-fingerprint stainless steel and reinforced glass, it invented the world’s first all-glass cabinet system, certified by Germany’s GS safety mark. Aluminum frames replace wood, reducing cabinet door thickness to 2-5mm while enhancing durability—achieving "less material, same quality" green design.

Yuman Home: China’s Green Manufacturing Benchmark

Collaborating with the Chinese Academy of Forestry, Yuman developed ENF+F4 dual-certified substrates with formaldehyde emissions below national standards. Its Shandong base achieved full-process low-carbon production, earning 2024 Shandong Province’s "Environmental Grade A". Modular cabinet designs enable disassembly/recycling, extending product lifespan beyond 15 years.

Technological Innovation: AI & Smart Manufacturing for Green Empowerment

AI-Driven Mass Customization

Zhongguancun’s "Kejin DeZhu" AI system handles 85% of routine inquiries via chatbots, freeing human agents for complex issues. In custom cabinetry, AI enables 3D space modeling and precision size matching. Combined with OSB board properties, it optimizes cutting plans, boosting material utilization by 20%.

Digital Twin Optimizes Production Flow

Germany’s Industry 4.0 leaders use digital twins to simulate factory processes. Real-time data adjusts production parameters, reducing energy waste. For instance, Chongqing Southwest Aluminum’s cold rolling oil mist recovery system generates ¥2 million annually from recycled organics, balancing environmental and economic benefits.

Challenges & Future: Building a Sustainable Ecosystem

Despite consensus on green transition, high costs and technical barriers hinder SMEs. Policy support—such as green loans and tax breaks—is critical. Chongqing’s "Industrial Green Efficiency Code" system integrates green evaluation, energy monitoring, and policy services via a digital platform, aiding over 1,000 enterprises in energy-carbon data coordination.

Future advancements in biodegradable plastics, recycled metals, and 3D printing will elevate the industry from "functional fulfillment" to "emotional resonance". As Valcucine designer Gabriele Centazzo states, "We’re not creating more—we’re choosing beautiful, sustainable solutions."

How to Make Traditional Kitchen Cabinets Look Modern

12 Reasons Why Custom Solid Wood Kitchen Cabinets Are the Only Investment That Truly Adds Value to Your Home

How to Maximize Storage Space with Kitchen Cabinet Inserts

What to Add to a Luxury Wardrobe Closet?

FAQ

What's MOQ for our kitchen cabinets, wardrobe cabinets or bathroom cabinets?

1 set.

What information are needed for getting a quote for our furniture cabinets?

Your size infomation or room drawings.

What's lead time for furniture cabinets?

It's about 20 - 30 days.

Can we ship the furniture cabinets to customer's port or city?

Yes. Please provide the city name or port name when you send us an inquiry.

Can we produce products according to customer's room size?

Yes. All our cabinets are custom size.

Premium Melamine Carcass Bathroom Vanity with Quartz Countertop | Foshan Murano Custom Solutions

T-shaped invisible door MA10

Flush panel door MA11

Siyun double wooden door MA12A

External flush right inward opening door MA13

Aluminum Frame Glass Hinged Door - MBB001

Aluminum Frame Glass Hinged Door - MBB003

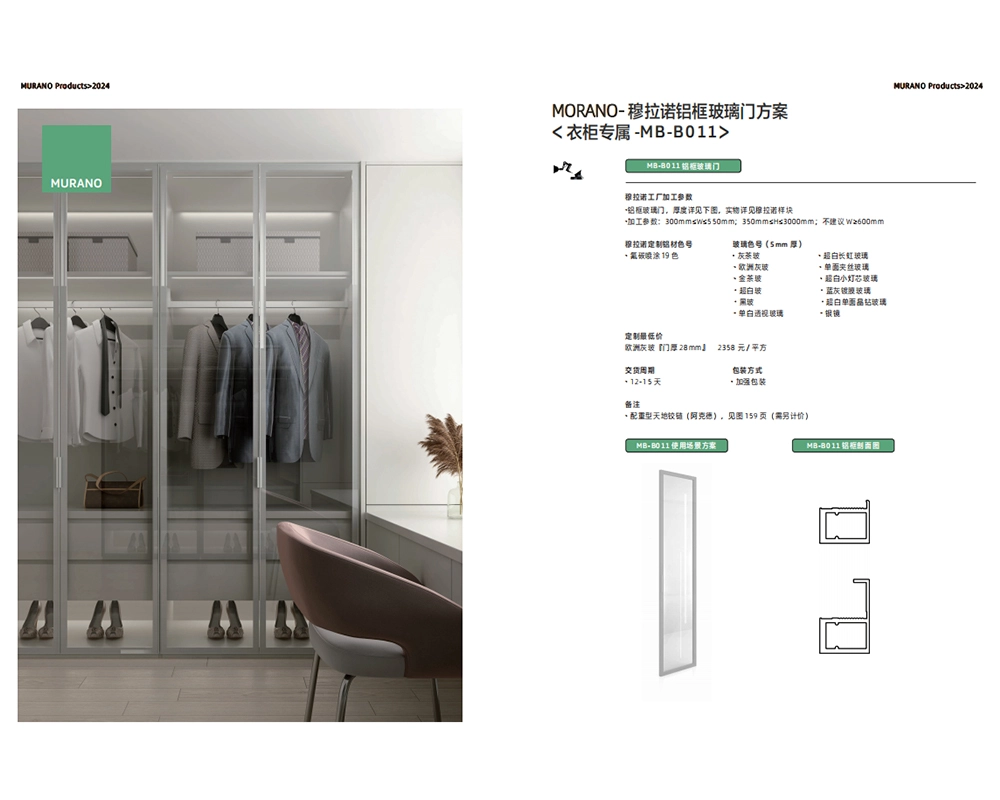

Aluminum Frame Glass Hinged Door - MBB011

Request a Free Consultation And Price Estimate

Get in touch with Murano today for a personalized consultation, and let us bring your vision to life. Fill out the form below or contact Murano directly to start your journey toward a beautifully tailored home!"

Scan QR Code

Scan QR Code

FoshanMuranoCabinet

foshanmuranocabinet

Whatsapp: +8618814138020

Scan QR Code