2026 Ultimate Guide to Manufactured Home Cabinets: Kitchen Trends and Modernization

- What makes manufactured home kitchen cabinets different from standard cabinetry?

- The Engineering Behind the Design

- Key Takeaways: Quick 2026 Modernization Summary

- Top Trends to Watch

- Modern Material Selection: Balancing Weight and Durability

- HPL vs. Melamine: The Moisture Battle

- Space-Saving Engineering for Manufactured Layouts

- Maximizing the "Cube"

- 2026 Design Trends: Colors and Finishes

- The New Aesthetic Palette

- Structural Considerations: When to Upgrade vs. Replace

- The "Weight Budget" Checklist

- Cost Analysis 2026: Budgeting for Your Remodel

- Budget Tiers

- Expert Tips: Common Mistakes to Avoid in Modular Remodels

- Professional Insights

- Conclusion

What makes manufactured home kitchen cabinets different from standard cabinetry?

Manufactured home cabinets are engineered with lightweight materials like vinyl-wrapped MDF and High-Pressure Laminate (HPL) to minimize load on the home's chassis. unlike standard site-built units, they often use non-standard dimensions (e.g., 21-inch depth) and specialized mounting systems to withstand transport vibration.

The Engineering Behind the Design

Manufactured homes are built on a steel chassis with specific weight capacities. Installing standard, solid-oak cabinetry can overload floor joists that were not designed for such dead loads. Lightweight kitchen cabinetry materials are not just a cost-saving measure; they are a structural necessity.

- Weight Ratios: Standard cabinets weigh 30-40% more than mobile home-specific units.

- Flexible Mounting: Cabinets are often secured with specialized fasteners that allow for the minor flexing of the home during settling or movement.

- Dimension Constraints: Narrower depths preserve walkway space in compact single-wide or double-wide layouts.

Key Takeaways: Quick 2026 Modernization Summary

The 2026 standard for manufactured home kitchens prioritizes moisture-resistant HPL surfaces, biophilic color palettes, and integrated smart technology. Modernization now focuses on "Invisible Tech," where charging ports and sensors are built directly into cabinet frames to maximize utility in small footprints.

Top Trends to Watch

To bring a prefabricated home into 2026, focus on these three pillars:

- Material Durability: Shift from paper-thin vinyl to moisture-resistant HPL cabinet surfaces that resist peeling in humid environments.

- Structural Safety: Adhering to mobile home cabinet structural weight limits by using engineered composites rather than heavy solid hardwoods.

- Smart Utility: Modular home smart kitchen integration is no longer a luxury but a standard, featuring motion-sensor under-cabinet lighting and hidden charging docks.

Modern Material Selection: Balancing Weight and Durability

For 2026, High-Pressure Laminate (HPL) is the superior choice over Melamine for manufactured homes due to its 6-8 layer resin construction that resists swelling. While Melamine is cost-effective, it lacks the impact resistance required for the tighter, high-traffic zones of a mobile home kitchen.

HPL vs. Melamine: The Moisture Battle

According to recent industry testing, HPL panels offer significantly higher resistance to water ingress compared to standard melamine. In a manufactured home, where humidity control can sometimes be a challenge, this difference is critical.

- HPL (High-Pressure Laminate): Created under 1,400+ PSI; highly resistant to scratches and moisture.

- Melamine (LPL): Created under low pressure (300-500 PSI); susceptible to edge swelling if seals fail.

- Thermofoil: Often peels when exposed to heat from ovens; 2026 trends are moving away from this in favor of seamless acrylics.

Experience Note: At Foshan Murano Smart Home Co., Ltd., we have observed a 40% increase in requests for HPL finishes in our global exports. Our custom wardrobe and cabinet solutions now predominantly feature these high-density composites to ensure longevity in diverse climates, a standard we apply rigidly across our 1,000+ completed projects worldwide.

Space-Saving Engineering for Manufactured Layouts

Pre-fabricated home kitchen layout optimization in 2026 relies on vertical utilization, such as floor-to-ceiling pantry pull-outs, to compensate for limited floor area. The goal is to increase cubic storage volume without expanding the cabinet footprint into narrow hallways.

Maximizing the "Cube"

In a single-wide or modular home, horizontal space is expensive. You must think vertically.

- Toe-Kick Drawers: Utilize the 4-inch gap beneath base cabinets for storing baking sheets.

- Blind Corner Solutions: Install "Magic Corner" pull-outs to access dead space in L-shaped kitchens.

- Vertical Pantry Towers: Replace standard 12-inch uppers with full-height 84-inch towers where possible.

2026 Design Trends: Colors and Finishes

Warm wood tones like medium oak and walnut are dethroning all-white kitchens, joined by earthy accents like Moss Green and Terracotta. According to the 2026 Houzz Kitchen Trends Study, 29% of homeowners are now choosing wood-tone cabinets, signaling a shift toward "Biophilic Design"—bringing the outdoors in.

The New Aesthetic Palette

- Earth-Centric Tones: Manufactured home cabinet kitchen designs are adopting "Moss Green" and "Warm Clay" to create a cozy, grounded feel.

- Two-Tone Modern: Dark lower cabinets (anchoring the space) paired with lighter, translucent or glass-front upper cabinets to make the room feel larger.

- Matte Finishes: High-gloss is being replaced by "Soft-Touch" matte finishes that hide fingerprints—essential in smaller homes where surfaces are touched frequently.

Structural Considerations: When to Upgrade vs. Replace

You must perform a "Weight Budget" calculation before remodeling; replacing lightweight originals with heavy stone counters and solid wood cabinets requires verifying floor joist capacity. Ignoring this can lead to floor sagging, door misalignment, and even chassis warping over time.

The "Weight Budget" Checklist

Before buying standard big-box store cabinets, consider:

- Subfloor Strength: Is it 5/8" particle board (common in older homes) or 3/4" plywood? The former requires reinforcement for heavy upgrades.

- Fastener Location: Manufactured homes often have wall studs spaced differently than site-built homes. You cannot simply screw a heavy cabinet into the wall paneling.

- Reinforcement: If upgrading to heavier hardware, reinforce the cabinet stiles (frames) or add blocking between wall studs.

Cost Analysis 2026: Budgeting for Your Remodel

A full kitchen cabinet replacement in a manufactured home averages between $5,000 and $9,000 in 2026, while a cosmetic refresh (paint/hardware) costs $1,000–$2,000. Costs have stabilized, but premium lightweight materials and smart integrations will push budgets higher.

Budget Tiers

- Entry-Level ($500 - $1,500): DIY painting using bonding primers (e.g., Zinsser BIN) and new hardware.

- Mid-Range ($2,500 - $5,000): Refacing doors and drawer fronts while keeping existing lightweight frames.

- Premium ($8,000+): Full custom installation using lightweight kitchen cabinetry materials like plywood or high-end HPL, including structural reinforcement and smart features.

Expert Tips: Common Mistakes to Avoid in Modular Remodels

The most critical mistake is installing standard 24-inch-deep base cabinets without measuring walkway clearance, which often chokes the flow of a narrow mobile home kitchen. Always verify depth requirements; many mobile homes require 21-inch-deep units.

Professional Insights

- Mistake: Using standard latex paint on laminate. Solution: Always use a bonding primer specifically formulated for glossy surfaces.

- Mistake: Ignoring the "Water Line." Solution: In manufactured homes, water damage spreads fast. Ensure all sink bases use waterproof materials like marine-grade plywood or PVC cores.

Experience Note: At Murano, our "Quality First" principle means we often advise clients against standard solid wood for modular projects. Instead, we recommend our specialized aluminum frame glass doors or high-density HPL panels. These provide the premium look of a modern home without the excessive weight that compromises a modular structure.

Conclusion

Modernizing manufactured home kitchen cabinet layouts requires a balance of style, weight management, and smart engineering. By choosing lightweight kitchen cabinetry materials, embracing 2026's warm earth tones, and integrating smart utility, you can increase your home's value without compromising its structural integrity. Whether you are refacing or replacing, prioritize moisture resistance and specialized sizing to ensure your renovation lasts for decades.

How to Make Traditional Kitchen Cabinets Look Modern

Custom Made Kitchen Cabinets vs. High-End Semi-Custom: The Definitive Quality & Durability Showdown (2026 Guide)

12 Reasons Why Custom Solid Wood Kitchen Cabinets Are the Only Investment That Truly Adds Value to Your Home

How to Maximize Storage Space with Kitchen Cabinet Inserts

FAQ

What's the payment terms of all our products?

T/T (30% inadvance, the balance shall be paid off before delivery), Western Union or L/C.

Can we produce products according to customer's room size?

Yes. All our cabinets are custom size.

What information are needed for getting a quote for our furniture cabinets?

Your size infomation or room drawings.

Can we ship the furniture cabinets to customer's port or city?

Yes. Please provide the city name or port name when you send us an inquiry.

What's MOQ for our kitchen cabinets, wardrobe cabinets or bathroom cabinets?

1 set.

T-shaped invisible door MA10

Flush panel door MA11

Siyun double wooden door MA12A

External flush right inward opening door MA13

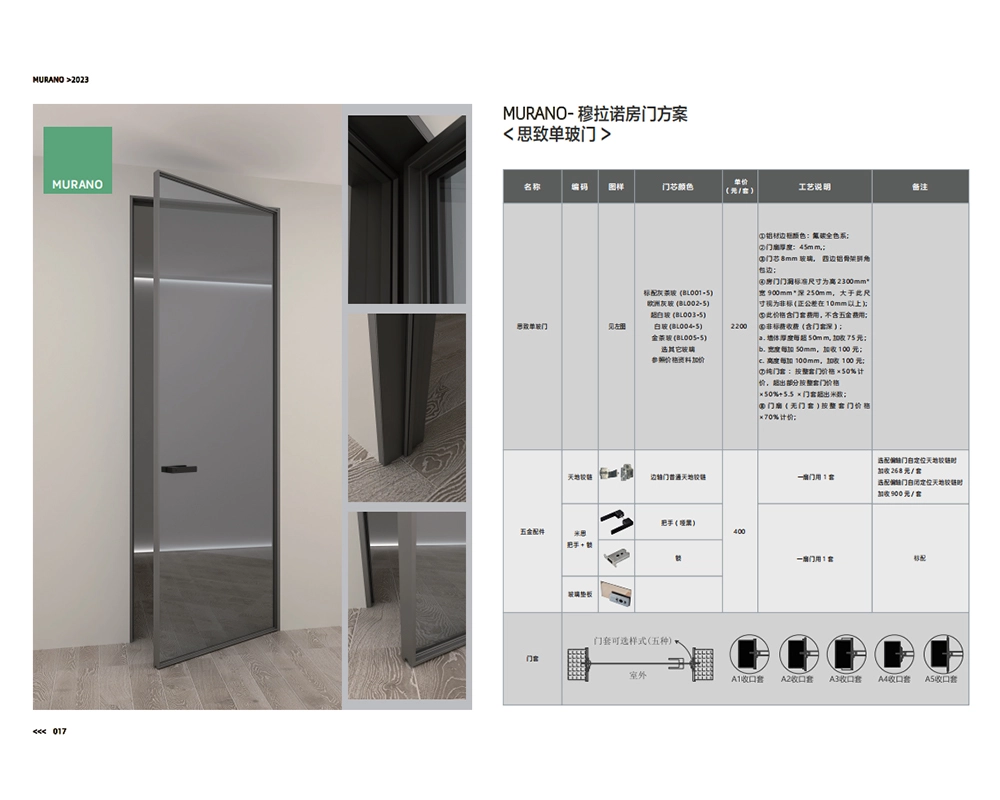

Aluminum Frame Glass Hinged Door - MBB001

Aluminum Frame Glass Hinged Door - MBB003

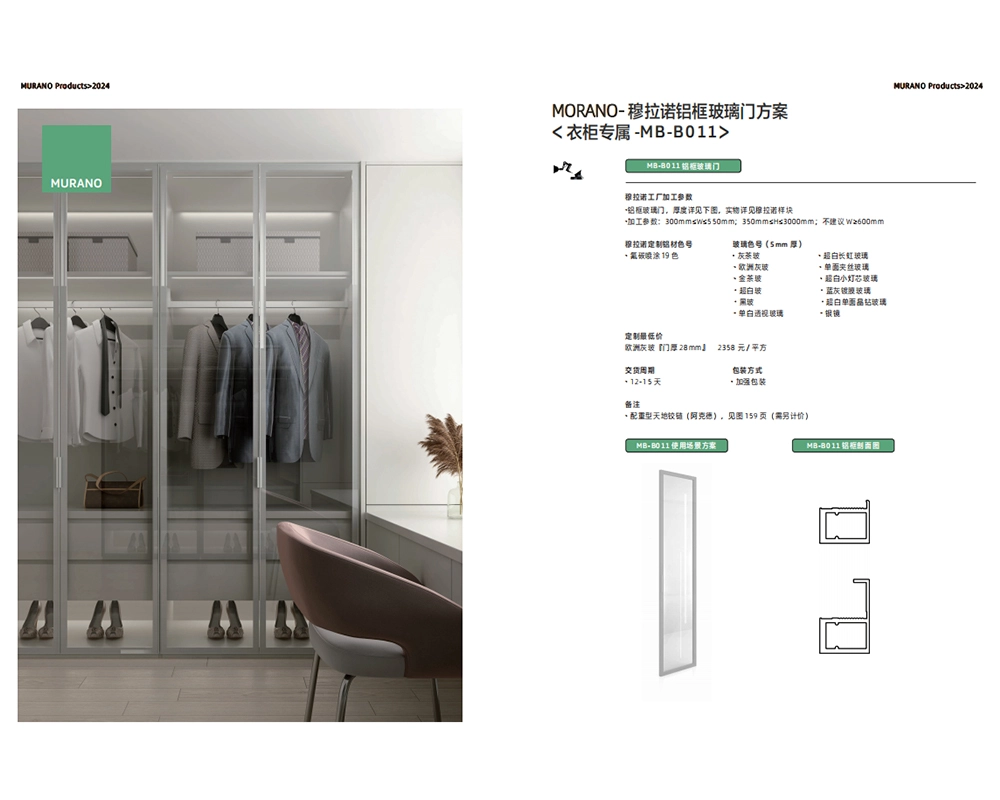

Aluminum Frame Glass Hinged Door - MBB011

SZ Single side glass interior door

Request a Free Consultation And Price Estimate

Get in touch with Murano today for a personalized consultation, and let us bring your vision to life. Fill out the form below or contact Murano directly to start your journey toward a beautifully tailored home!"

Scan QR Code

Scan QR Code

FoshanMuranoCabinet

foshanmuranocabinet

Whatsapp: +8618814138020

Scan QR Code