Smart Factory Revolution in Cabinet Customization—Global Manufacturers' Digital Transformation Path

Explore how global cabinet manufacturers are leveraging IoT, AI, and smart factories to revolutionize custom cabinet production, enhance efficiency, and meet sustainability demands in the digital age.

Introduction: The Digital Transformation Imperative

The global cabinet customization market is undergoing a paradigm shift driven by smart factory technologies and digital transformation. Manufacturers worldwide are integrating IoT, AI, and big data analytics to optimize production workflows, reduce waste, and deliver personalized solutions at scale. This revolution is not just about automation—it’s about redefining how custom cabinets are designed, produced, and delivered to meet evolving consumer demands for sustainability, functionality, and speed.

Technology-Driven Efficiency: The Backbone of Smart Factories

IoT and Real-Time Monitoring

IoT sensors embedded in machinery enable real-time monitoring of production lines, reducing downtime by 30% and enhancing quality control. For example, Germany’s Schinning employs IoT-enabled precision saws and IMA’s flexible edge banding machines to achieve 0.1mm cutting accuracy, slashing production cycles by 40%.

AI and Predictive Analytics

AI-powered systems analyze historical data to predict maintenance needs, optimize material usage, and automate design processes. China’s QuanU Home Furnishing uses HPO software in its “Green Smart Manufacturing 4.0 Factory” to batch-process same-color panels, boosting material utilization by 15%.

Cloud-Based Collaboration Platforms

Digital platforms like Cetec ERP and Infor SyteLine streamline data integration from quoting to production, as seen in Reid MFG’s transformation. This reduces operational inefficiencies by 25% and accelerates order fulfillment.

Case Studies: Pioneering Digital Transformation

Herman Miller’s Sustainable Scaling

The global furniture leader leverages Infor SyteLine to enhance supply chain visibility, reduce inventory waste, and uphold environmental principles across 40+ countries.

Cabinet Warehouses’ E-Commerce Expansion

By adopting user-friendly digital platforms inspired by government service portals, Cabinet Warehouses expanded its online reach, tapping into the 30% market share held by modular cabinets in North America.

Dura Supreme’s Localized Production Strategy

To counteract U.S. CVD tariffs, Dura Supreme established a North Carolina factory, optimizing supply chains while maintaining quality—a strategy mirrored by Chinese manufacturers targeting Asia-Pacific markets.

Market Trends: Sustainability and Consumer-Centric Design

Rising Demand for Eco-Friendly Materials

Europe leads with 35% of cabinets using FSC-certified wood or recycled plastics. China’s TUBAO Super E0 Board, with formaldehyde emissions below 0.03mg/m³, dominates second-tier cities, reflecting a 78% global consumer preference for eco-friendly options.

Smart Cabinet Integration

Asia-Pacific markets prioritize smart features: automatic lighting, embedded appliances, and waste management systems. Europe’s 3D virtual design platforms enable “what-you-see-is-what-you-get” customization, while North America’s modular systems offer flexible assembly for DIY enthusiasts.

Challenges and Future Outlook

Cost Volatility and Trade Barriers

Raw material fluctuations and anti-dumping duties (e.g., U.S. CVD tariffs) pressure manufacturers to adopt localized production. Solutions include regional factories and AI-driven supply chain optimization.

The Road Ahead

By 2030, the global cabinet market is projected to grow at 1.3% CAGR, driven by frameless designs, multifamily housing demand, and e-commerce penetration. Sustainability mandates will push 48% of residential applications toward certified materials, while AI and IoT will further automate quality control and predictive maintenance.

Conclusion: Embracing the Digital Future

The smart factory revolution is redefining cabinet customization—balancing personalization, efficiency, and sustainability. Manufacturers who invest in digital transformation today will lead the market tomorrow, turning challenges like trade barriers into opportunities for innovation and growth.

How to Make Traditional Kitchen Cabinets Look Modern

How to Maximize Storage Space with Kitchen Cabinet Inserts

What to Add to a Luxury Wardrobe Closet?

How to Design Functional Kitchen and Joinery for Small Spaces?

FAQ

Can we ship the furniture cabinets to customer's port or city?

Yes. Please provide the city name or port name when you send us an inquiry.

What's lead time for furniture cabinets?

It's about 20 - 30 days.

Can we produce products according to customer's room size?

Yes. All our cabinets are custom size.

What's the payment terms of all our products?

T/T (30% inadvance, the balance shall be paid off before delivery), Western Union or L/C.

What's MOQ for our kitchen cabinets, wardrobe cabinets or bathroom cabinets?

1 set.

T-shaped invisible door MA10

Flush panel door MA11

Siyun double wooden door MA12A

External flush right inward opening door MA13

Aluminum Frame Glass Hinged Door - MBB001

Aluminum Frame Glass Hinged Door - MBB003

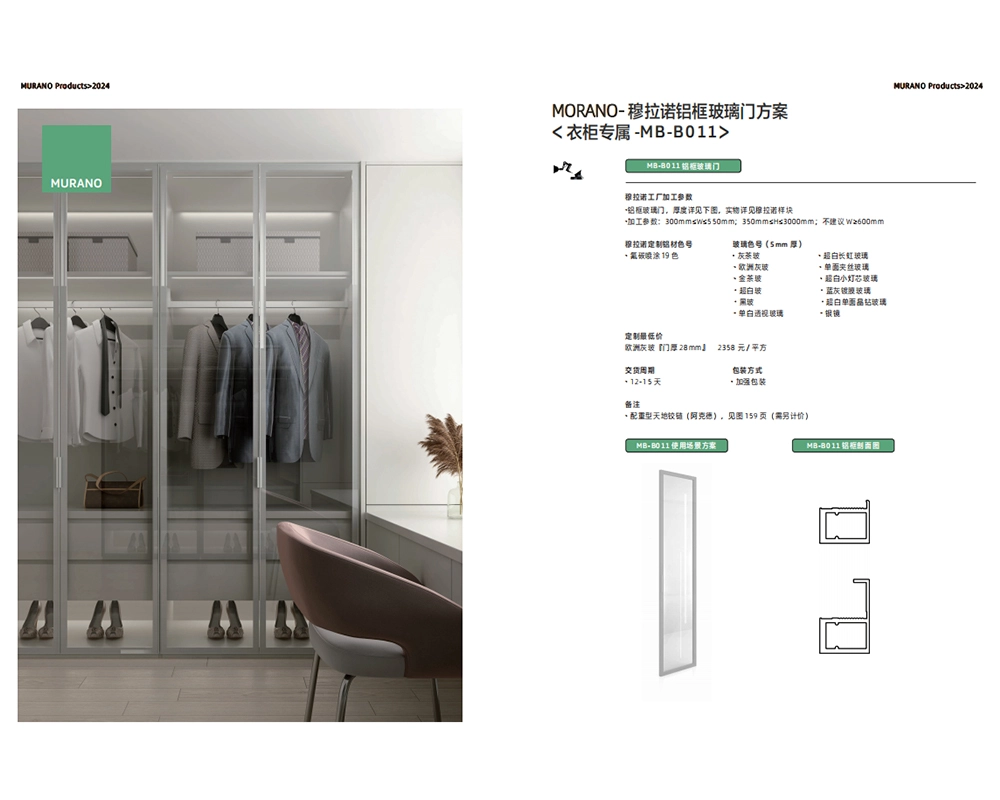

Aluminum Frame Glass Hinged Door - MBB011

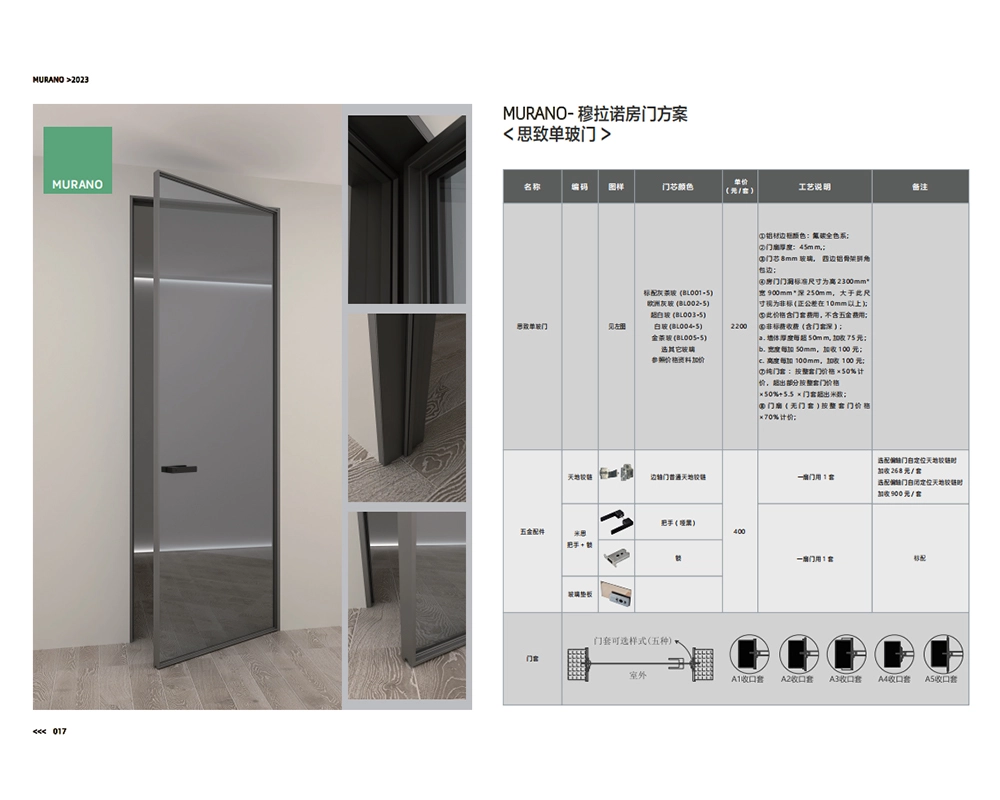

SZ Single side glass interior door

Request a Free Consultation And Price Estimate

Get in touch with Murano today for a personalized consultation, and let us bring your vision to life. Fill out the form below or contact Murano directly to start your journey toward a beautifully tailored home!"

Scan QR Code

Scan QR Code

FoshanMuranoCabinet

foshanmuranocabinet

Whatsapp: +8618814138020

Scan QR Code